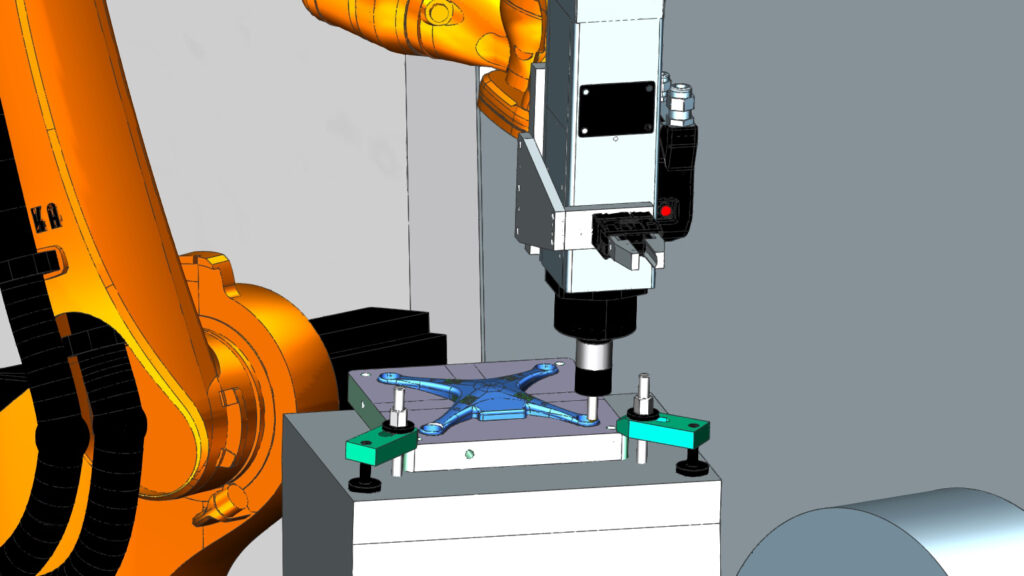

Digitally transform part manufacturing using one integrated software system to program CNC machine tools, control robotic cells, drive 3D printers and monitor product quality.

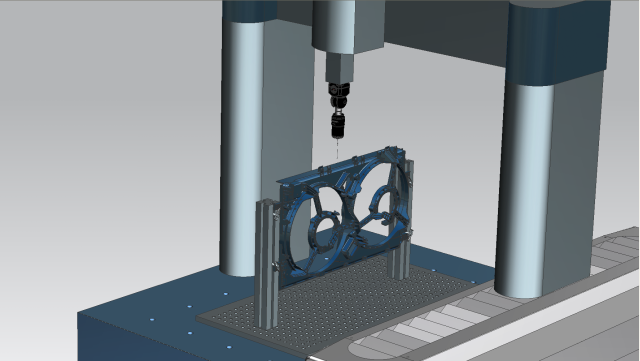

Digitalize your quality control process to meet demanding requirements for product quality and dimensional accuracy. By integrating CMM inspection programming, shop floor execution, and measured data analysis, you can establish an efficient data-driven quality control process.

This automated, closed-loop solution enables continuous process control, so you can deliver high-quality products and stay competitive.

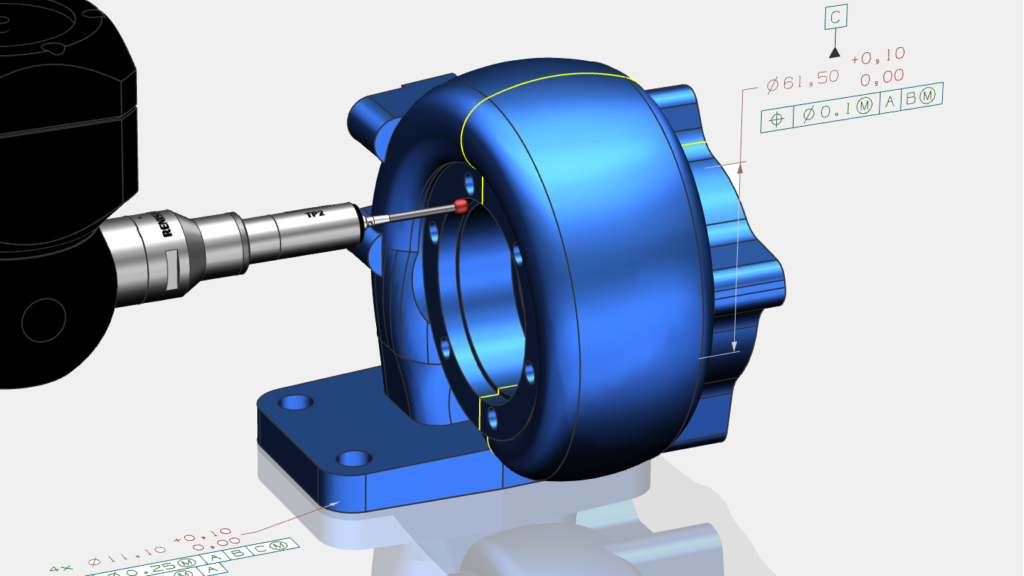

Generate inspection programs automatically by using the part geometry and product and manufacturing information (PMI) that is associated with intelligent CAD models.

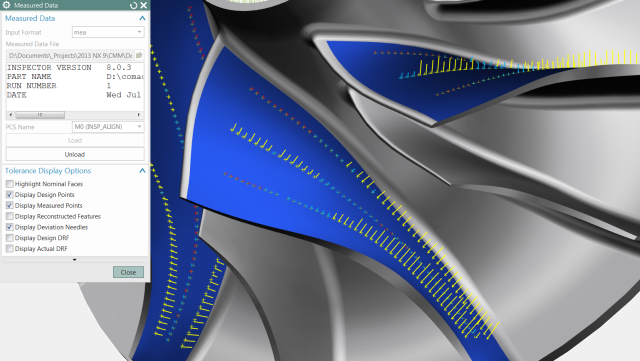

Easily compare as-built measured results against the as-designed 3D geometry. You can visualize the measurement results in NX and perform analysis in the context of the digital part model.

Run consistent and accurate in-process inspection and measured data analysis of manufactured parts using CMM equipment and inspection-ready CNC machines.

Digitally transform part manufacturing using one integrated software system to program CNC machine tools, control robotic cells, drive 3D printers and monitor product quality.