Digitally transform part manufacturing using one integrated software system to program CNC machine tools, control robotic cells, drive 3D printers and monitor product quality.

Siemens Digital Industries Software provides all the necessary capabilities for additive manufacturing, from design to print to post-print validation. Our products help you to industrialize additive manufacturing so you can not only prototype but also manufacture ground-breaking products at scale with this exciting new technology. Learn about the software available for the different steps of the additive manufacturing end-to-end workflow below.

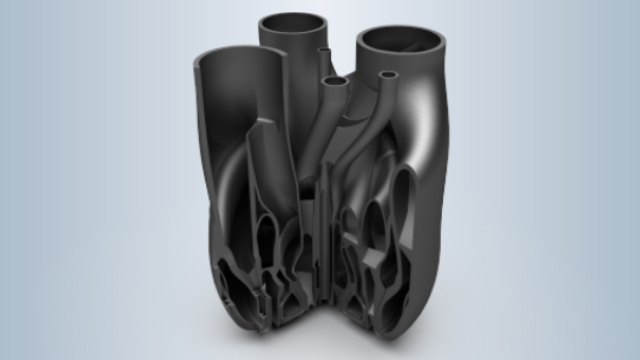

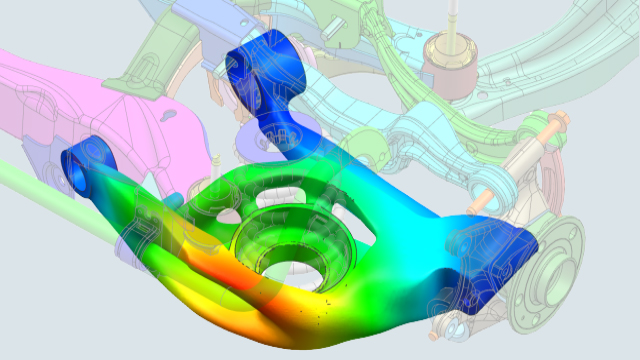

NX allows you to create optimal part designs for additive manufacturing with integrated generative engineering tools like design space exploration and various flavors of topology optimization.

The beginning of a quality additive manufacturing process is always in the design. Additive manufacturing provides the ability to manufacture highly complex designs with features like optimized surfaces and lattice structures. Siemens Digital Industries Software AM solutions allow you to design and print complex geometries at scale.

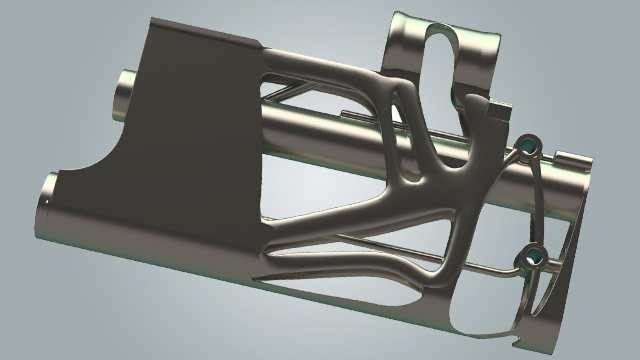

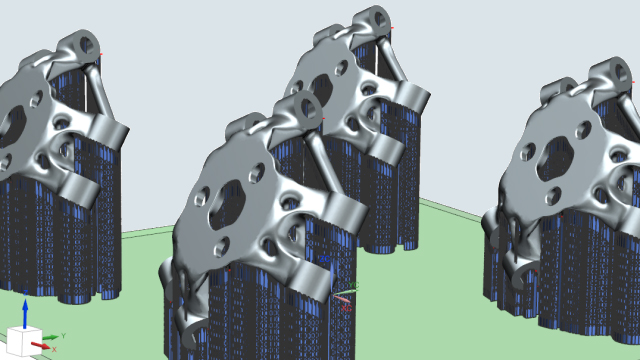

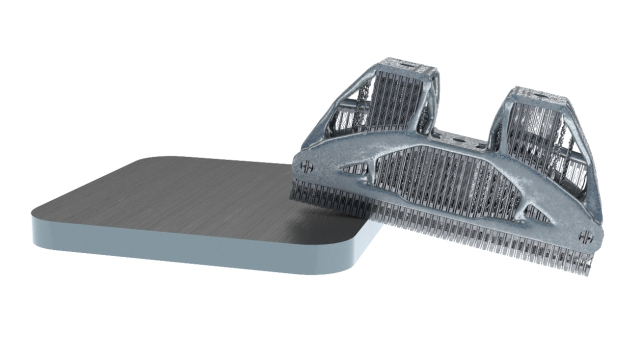

Quality, efficient output from the AM process requires the proper setup. The integrated build preparation tools in NX assist with placing, orienting, and supporting parts in the build tray in the most efficient manner possible.

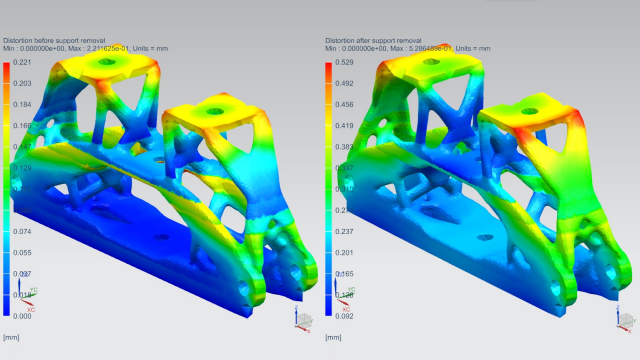

Simulation of the build process can help you generate quality 3D prints at scale. From build orientation optimization to meso-scale deposition path optimization, NX has the tools you need to print successfully the first time.

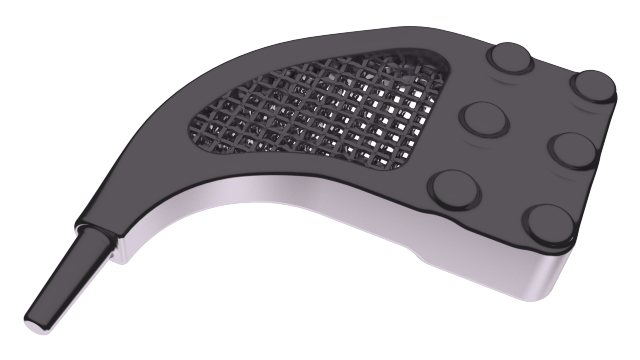

NX allows the designer and manufacturer to validate their AM parts at every step along the way. Validate the printability of your part and then simulate its performance in the field with integrated tools to help you print production-ready parts.

Connect to the widest range of 3D printing hardware with Siemens NX. Regardless of whether you’re printing on a planar powder bed system or a multi-material, multi-axis system, NX has you covered.

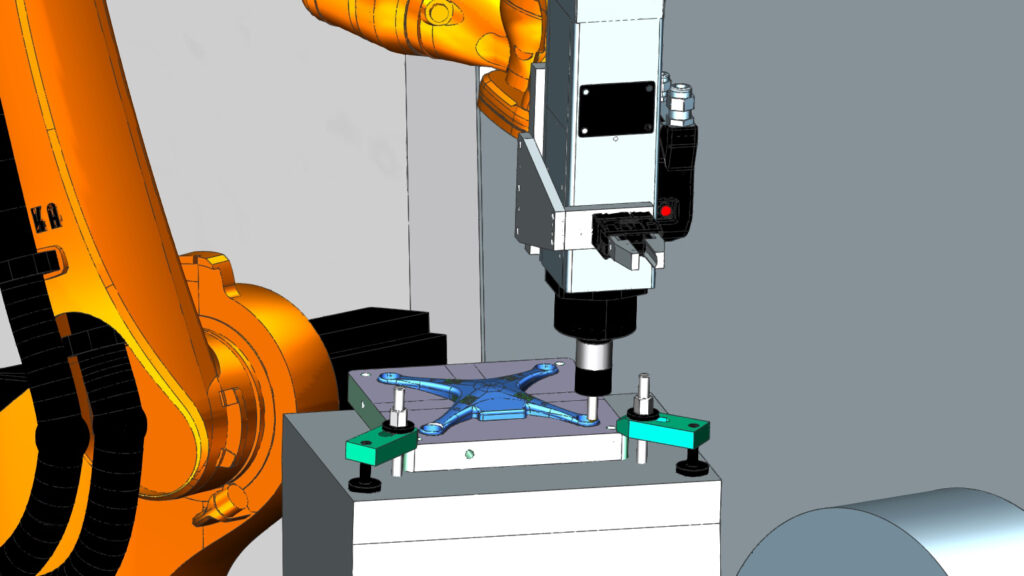

Industrialized 3D printing requires robust post-processing software like that in NX. Printing is not the last step in the additive manufacturing process. Powder removal, removal of the part from the build tray, and post-process machining are all aspects of the full AM process, and all of these functions are part of the Siemens AM solution set.

When considering additive manufacturing as a production process, companies often partner with a print provider and as such must consider many factors. Siemens’ Additive Manufacturing Network (AMN) provides an online order-to-delivery collaboration platform to co-create AM parts with a comprehensive ecosystem of AM manufacturers. It brings the right people together to deliver on manufacturing needs, while instantly locating suppliers and consultants in local or preferred geographic areas.

The Siemens Opcenter solutions allow you to manage your additive manufacturing production. Operators can schedule, execute, and monitor AM production with full operational visibility to ensure optimal quality and efficiency. Operators can also use the Opcenter solutions to visualize material flow throughout a facility to ensure that the proper mix of recycled and virgin material is being used for the various print jobs executing throughout the factory.

In order to get the most from the additive manufacturing process, companies need a quality AM process with a strong set of IoT and analytics solutions. Siemens provides the ability to monitor the additive manufacturing process, analyze the resulting data, and act upon that data with part and process improvements. This close feedback loop allows companies to feed insights back into upstream phases of the additive manufacturing process to optimize next-generation innovation.

Digitally transform part manufacturing using one integrated software system to program CNC machine tools, control robotic cells, drive 3D printers and monitor product quality.