Course Duration 1 Month

Time: 2 Hours Daily

- Concept Design

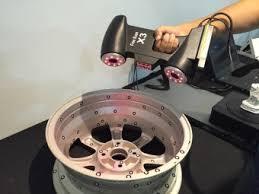

- 3D Scanning (Laser and White Light / Blue Light Scanning)

- Scanned Data to 3D CAD Modelling

- 3D Inspection & Report

- Scanned Data to Model Comparison

- CNC Programming

- 3D Printing – RPT Service

Course Duration 1 Month

Time: 2 Hours Daily

The course will teach the students the different methods of importing, parsing, manipulating, and modifying 3D data. The course will also equip the students to analyze the structure, function, and operations of a product. The students will also learn the applications of computed tomography scanning, 3D optical scanning, digital archiving, class ‘A’ surfacing and much more.

Course Duration 1 Month

Time: 2 Hours Daily

We can take your ideas / vision and sketch-out and develop preliminary products based on those concepts.

What is Concept Design?

Concept engineering is the process of translating customer needs to design features and measurable performance parameters.

We can also say: Define shape first & size later.

Following is the example for concept design to explaining whole process, how imagination (shape) from customer is translated to Parametric Design to emerge Actual Product.

New Concept

We have a complete toolset for turning raw 3D scan data into high quality, watertight polygon mesh models for use in downstream applications, including Scanning / Inspection software.

Live Inspect technology for real-time inspection results from handheld 3D scanners.

Automatic scan data alignment

3D & 2D deviation analysis

3D & 2D GD&T

3D Scanned Data to 3D CAD Modelling

Any Physical model can be reengineered or duplicated for some change or for Inspection by digitizing / scanning with the help of 3D white Light Scanner. 3D model can also be made for the subsequent engineering drawing.

The process of analysing an existing design to identify its components and their interrelationships and create representations of the design in another form or at a higher level of abstraction.

Reverse engineering is usually undertaken in order to redesign the existing design for better maintainability or to produce a copy of a same without access to the design from which it was originally produced.

Traditional method to develop a design from existing product is very tedious & time consuming which in turn was affecting the cost of product.

Incas of complicated contours, (i.e. non-measurable shape, variable radius) makes reverse engineering of product more difficult & time consuming, resulting in repetitive reworks & changes in design which increases cost of a product.

White light scanner has created a new revolution in reverse engineering process. Time period for developing reverse product has drastically reduced from month to days.

Reviews

There are no reviews yet.